About Our Customisation Methods

Embroidery

Embroidery is the process by which a badge is sewn into a garment using a computerised embroidery machine. This process gives a high quality and long lasting finish that is most suitable for club badges and small logos to be placed on a garments chests, sleeves or trouser legs.

In order for us to produce an embroidered badge we need a convert the file into a .dst file - this is the format that the embroidery machine can read. This is know as the digitisation process, there is a standard one off charge of £15.00 +VAT so we can set your badge up. Once your badge is set up, the standard price for an embroidered badge is £4.50 +VAT, however this can change depending on the size and/or quantity.

If your badge is newly set up, we will send you a visual run off of the badge which will need to be signed off before we can embroider the badge onto your garments. At this stage, you can make changes to your badge to ensure it looks as you would like.

Embroidery Pros

- Long lasting - as embroidery is done with thread, it will hold up to daily wear and washing. An embroidered badge will often outlast the garment is is embroidered on provided it is looked after correctly

- High quality finish - whilst other methods of customisation have different qualities/suitabilities, in our opinion nothing looks better than an embroidered logo when done correctly

- Suitable a wide variety of products - embroidery can be used in circumstances where printing is not an option, such as on fleeces, hats and caps

Embroidery Cons

- Can become more expensive than other methods of customisation - depending on size and positioning of the logo, it can become very costly. We would always recommend printing customisation such as sponsor logos for example

- Loss of detail in some logos - we do not recommend embroidery when there is a gradient colour change in logos. It is also difficult to make small text easily readable

Printing

We offer multiple different methods of printing, such as one colour vinyl, full colour vinyl, direct to garment printing.

One Colour/Full Colour Vinyl Printing

Vinyl printing is the process of cutting and weeding vinyl to be printed on top of the garment. This gives a clear, vibrant finish that is perfect for customisation such as printed names, numbers, initials, text and sponsor logos.

In order to print vinyl we need the logo to be in a vector format (.ai, .pd., eps files). This allows the machine to print and cut the outline of the logo into the vinyl, so it can be weeded into the correct shape before being heat pressed onto the garment. If you do not have this type of file we offer a logo redraw service for £10.00 +VAT - just send us the best, clearest version of your logo you have and we will do the rest.

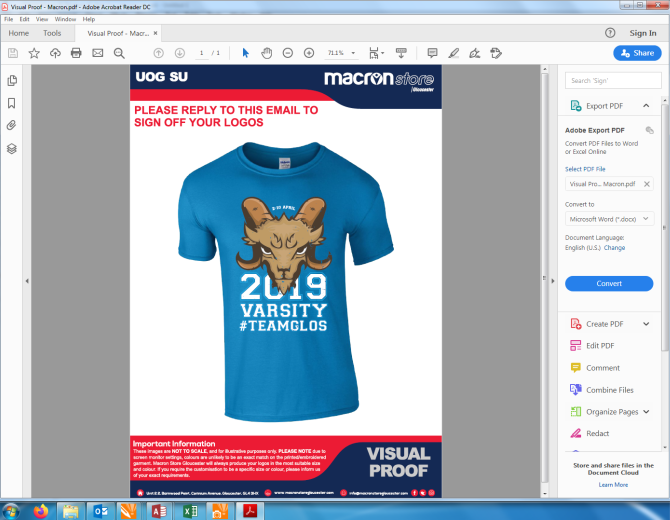

If your logo is newly set up, we will provide you with a visual mock-up created by our in-house design team. This mock-up will need to be signed off before we print your items, and you can make any changes needed to ensure your logo looks as you would like. There may be limitations to your logo which can affect the design, however we will provide you with multiple options on your mock-up. Any changes that have been made to your logo on mock-ups will be explained to you by the sales team.

Vinyl Printing Pros

- Perfect for names, numbers, initials and sponsor logos

- Clear/vibrant finish

- Cost effective

Vinyl Printing Cons

- Durability - as vinyl is printed on top of the garment, it can be liable to cracking and peeling after multiple washes

- Can be difficult to produce small text and details on one colour vinyl. The solution to to this is adding an outline to the logo and printing on full colour vinyl

Direct to Film (DTF) Printing

DTF printing is the process in which a logo is printed directly onto a film, before being applied to the garments via a heat press. It is great for large complex designs, whilst still providing a premium finish.

The process is much the same as a regular inkjet printer, with the printer spraying ink onto the film through print heads. A "glue" is then applied to the ink, before being sealed via a heater. The individual logos can then be cut out off the film, the applied to the garments using a heat press.

We can print any logo format on the printer, however the logos will appear on the garment exactly as they appear on screen - if the logo is pixelated, the print will be pixelated. Vector file formats work best as they can be resized without any pixelation, however any high resolution .jpeg or .png will be look fine. If required, we will send a visual mock-up of of the design to you to sign of before we print the garments.

DTF Printing Pros

- Produces a high quality, long lasting finish as deign is printed into the garments

- Great option for large designs with multiple colours

- Does not require logo in a vector format (although this helps)

DTF Printing Cons

- Variable cost depending on size of logo/colour of the garment it is being printed on

- Customisation placements can be limiting